Join

Proto save

£0.43

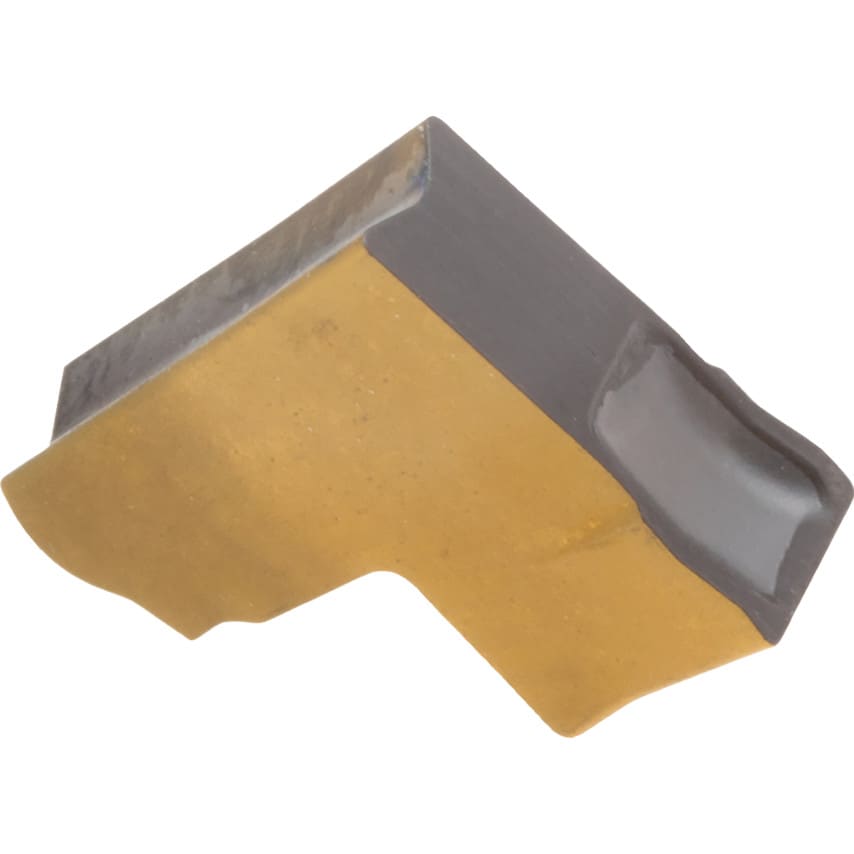

A tough submicron substrate improved TiAIN PVD coated grade for better chip

flow. Designed for machining heat resistant alloys, austenitic stainless steel, hard alloys and carbon steel at medium to high cutting speeds, interrupted cut and unfavourable conditions. Excellent notch wear and built-up edge resistance.

Features and Benefits

Tough submicron substrate for greater tool hardness

Excellent notch wear and built-up edge resistance

TiAIN PVD coated for better chip flow, heat and wear resistance

Typical Applications

Parting

Grooving

Steel

Stainless steel

| ISO Category Grade | M | P |

| Material | Carbide |

| ISO Designation | TAG N3C |

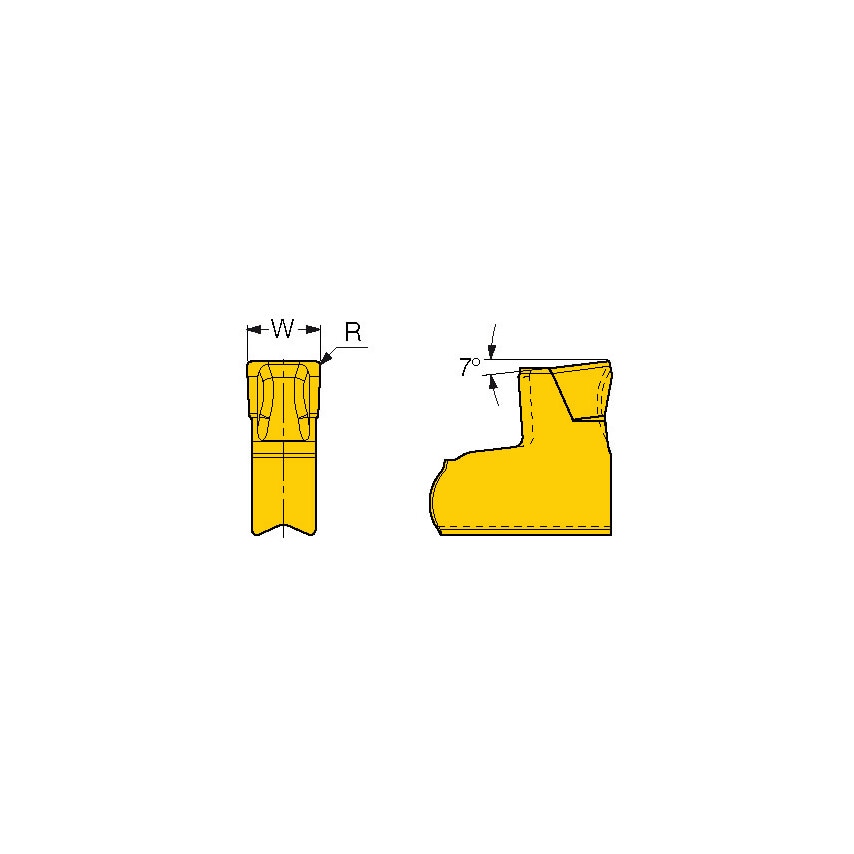

| Cutting Direction | Neutral |

| Insert Holding Type | Self Grip |

| Cutting Application | Grooving | Parting |

| Manufacturer Grade | IC830 |

| Insert Style | TAG |

| Grooving Width | 3.05mm |

| Radius Type | Corner Radius |

| Chipbreaker | C |

| Cutting Location | External |

| Series | Tang-Grip |

| Finish/Coating | Multilayer TiAlN/TiN |

| Compatible Materials | High-Temperature Alloys | Stainless Steel | Steel |

| Corner Radius | 0.2mm |

| MFR Part No. | 6011386 |

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.