Join

Proto save

£0.26

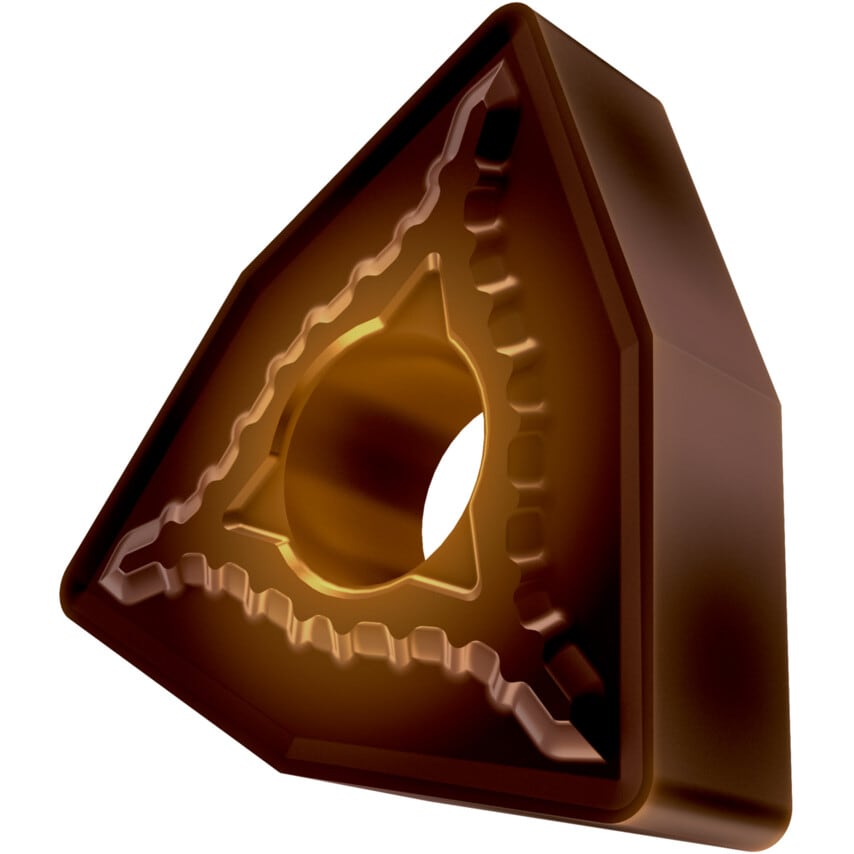

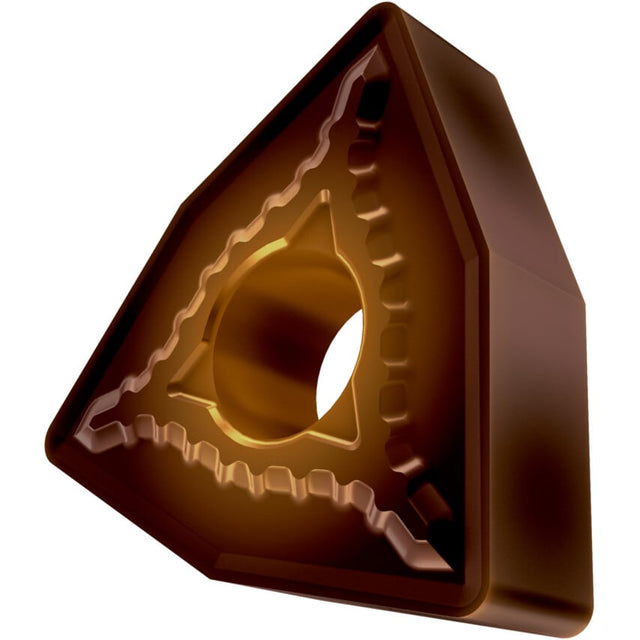

Enhance machining efficiency with the double-sided negative turning insert from Dormer Pramet. Designed for fine to heavy machining of steels and stainless steels, the eighty-degree trigon design, coupled with ISO-tolerance class-M accuracy, ensures precision in a diverse range of applications.

Features and Benefits

3-D chip-breaker ensures precise chip-breaking control across a wide range of feeds and depths of cut

Wide chip groove enhances chip control for improved evacuation when machining tough materials

Raised chip-breaker back wall height forces tighter chip curls, improving chip-breaking for tough materials at lower feeds

Neutral geometry increases impact resistance, enabling machining with heavier feed and higher depth of cut

WC-Co-based substrate, submicron-grained, offers high hardness, abrasive wear resistance, and resistance against comb cracks

PVD coating enhances thermal cracking resistance and performance in operations with cutting temperature fluctuations

Multi-layered PVD coating optimised for increased productivity and durability, with a thick TiN coating for crater wear resistance and a hard AlTiN layer for flank wear resistance

Unique Titanium-Boron-Nitride (TiBN) top layer reduces build-up edge and enhances overall performance

Typical Applications

Steel

Stainless steel

| ISO Cut | M20-M35 | P20-P40 |

| Material Application | Stainless Steels | Steels |

| Chipbreaker | SM |

| Insert Size | 8 |

| Shape | 80\u00b0 Trigon |

| MFR Part No. | 7977444 |

| Cutting Edge Length | 8.7mm |

| Inscribed Circle | 12.7mm |

| Thickness | 4.76mm |

| Finish/Coating | PVD |

| Corner Radius | 1.2mm |

| Material | Carbide |

| Insert Style | WNMG |

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.