Join

Proto save

£0.56

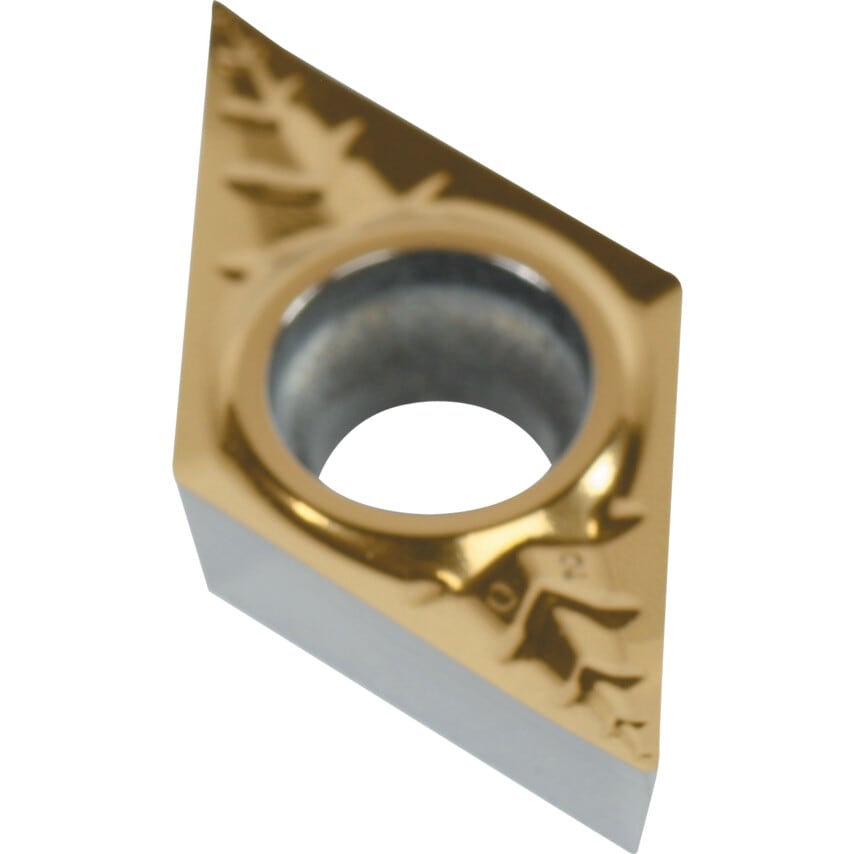

DCGX Turning Inserts

55 Rhombic Inert

Fits the same Internal/External Toolholders as DCGT

Insert Geometry for Finishing & Semi-finishing of Aluminium & Aluminium Alloys

Optimised edge and radius geometry.

Improved surface finish.

Improved chip control.

'G' Tolerance for high repeatability.

First choice for machining pure aluminium.

30% longer insert life compared to uncoated grade.

Insert Grade K10C

ISO N05-N15 PVD Coated. Micrograin carbide for machining aluminium and aluminium alloys, 30% higher tool life against uncoated grade. Smooth coating and polished surface gives better chip control.

ALC Geometry

For finishing & semi finishing of aluminium and aluminium alloys. A unique breaker design gives a sharp cutting edge and positive rake angle. Special edge preparation and surface treatment produce better surface quality and greater chip control, reduced friction and vibration. 'G' tolerance inserts for higher repeatability.

| Manufacturer Grade | K10C |

| ISO Cut | N05 to N15 |

| Thickness | 2.38mm |

| ISO Category Grade | N |

| Cutting Direction | Neutral |

| Corner Radius | 0.4 |

| Material Application | Aluminium | Aluminium Alloys |

| Pack Quantity | 1 |

| Material | Carbide |

| Cutting Edge Length | 7.8mm |

| Insert Size | 070204 |

| Clearance Angle | 7\u00b0 |

| ISO Designation | DCGX 070204-ALC |

| ISO Category | N |

| Chipbreaker | ALC |

| MFR Part No. | DCGX070204-LC YBG101 |

| Shape | 55\u00b0 Rhombic |

| Inscribed Circle | 6.35mm |

| Insert Style | DCGX |

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.