Join

Proto save

£1.22

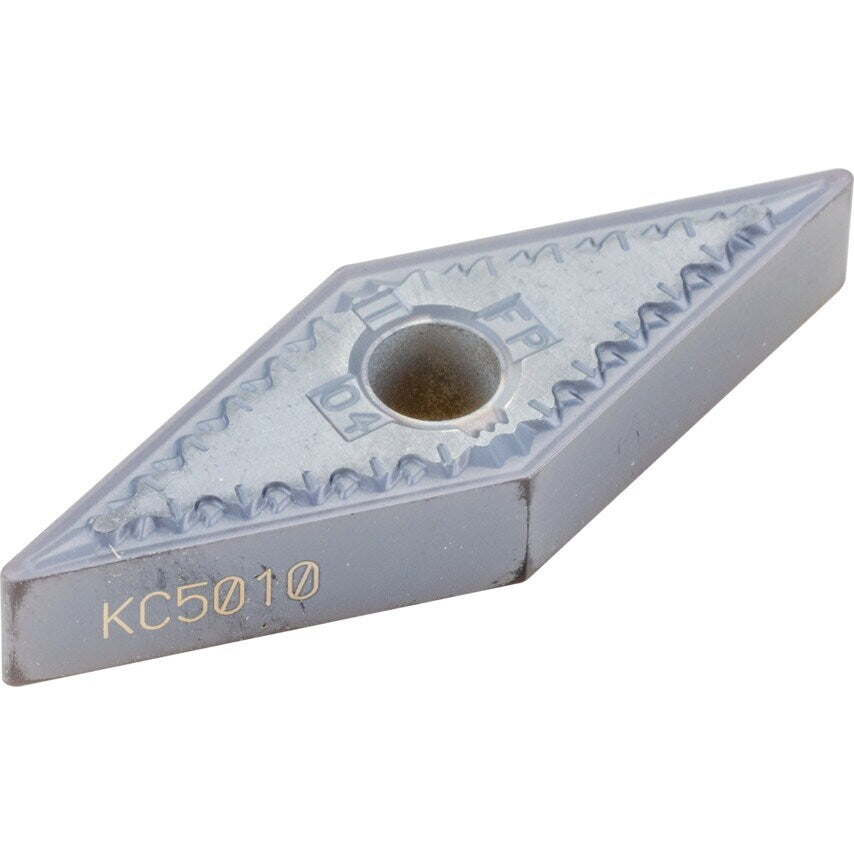

VNMG-FP Kenloc negative turning inserts feature an advanced PVD AlTiN coating over a very deformation-resistant unalloyed carbide substrate. This new and improved coating enables machining speeds to be increased by 50-100%.

The KC5010 grade is ideal for finishing to general machining of most work-piece materials at higher speeds, including most steels, stainless steels, cast irons, non-ferrous materials, and super alloys under stable conditions. additionally this grade also performs well machining hardened and short chipping materials.

Features and Benefits

Unalloyed carbide substrate provides deformation-resistance at higher speeds

PVD AlTiN coating enables machining speeds to be increased by 50-100%

Ideal for finishing to general machining of most work-piece materials

Performs well machining hardened and short chipping materials

Typical Applications

Turning

Steels (most)

Stainless steels

Cast irons

Non-ferrous materials

Super alloys

Hardened and short chipping materials

| Material Application | Steels |

| Finish/Coating | PVD-AlTiN |

| Insert Size | 160404FP |

| Manufacturer Grade | KC5010 |

| Material | Carbide |

| ISO Category Grade | P |

| Insert Style | VNMG |

| Product Type | Turning Inserts |

| MFR Part No. | 1819513 |

| Chipbreaker | FP |

| ISO Designation | VNMG 160404FP |

Payment & Security

Payment methods

Your payment information is processed securely. We do not store credit card details nor have access to your credit card information.